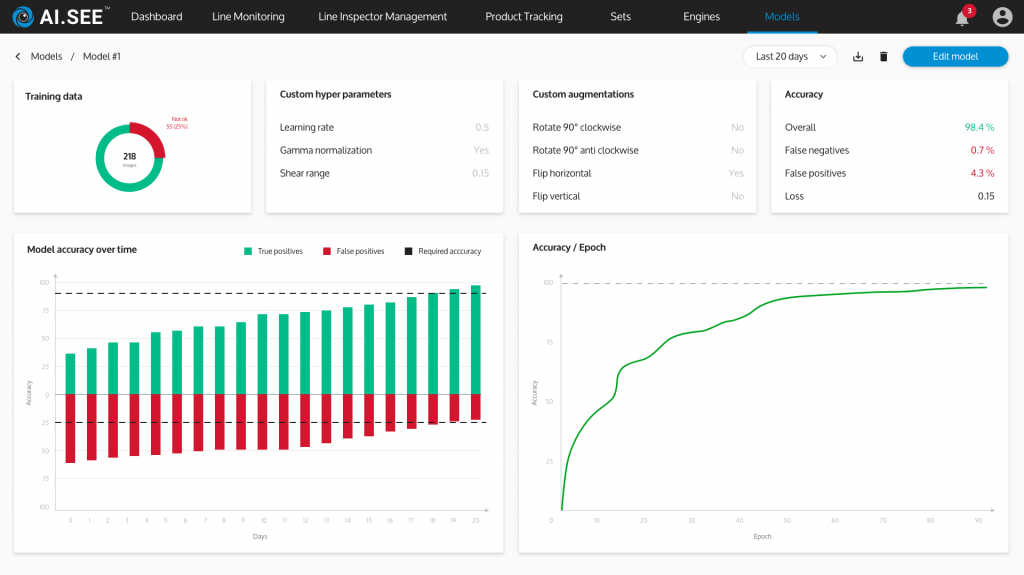

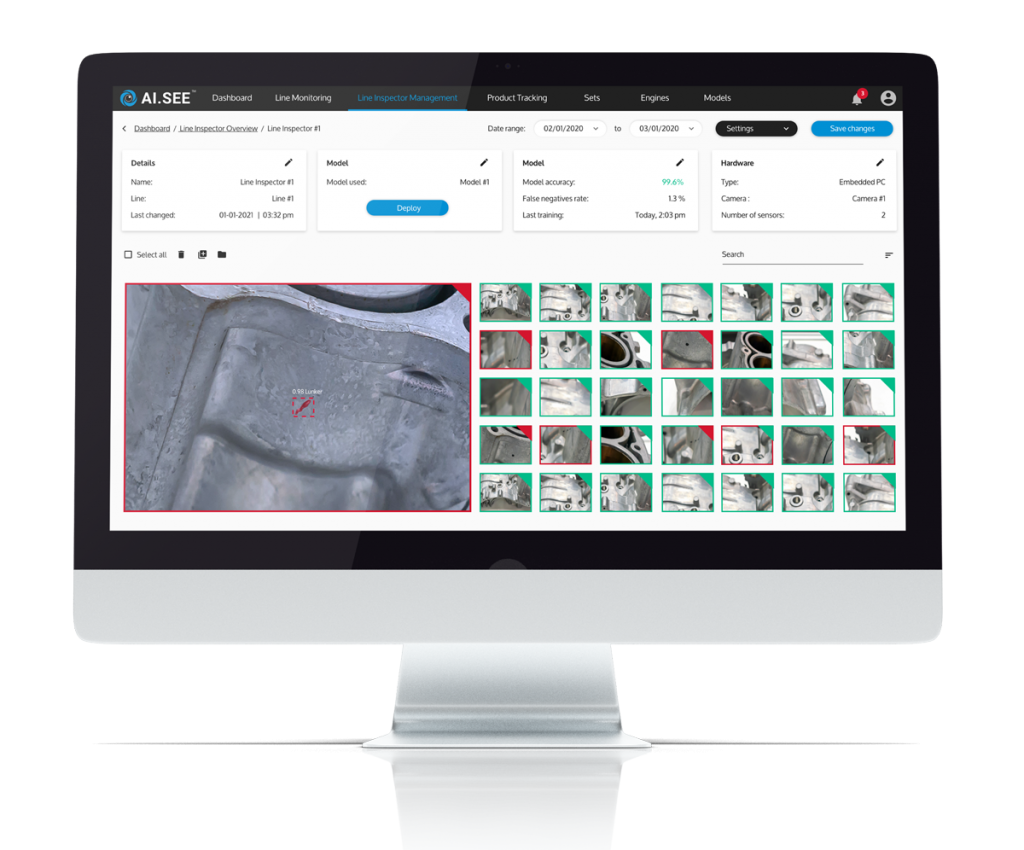

With AI.SEE™ Core, you can pool and manage the AI-driven quality inspections across all your AI.SEE™ inspection cells used in production. AI.SEE™ automatically trains the AI-assisted, self-learning, neural-network-based error-detection algorithm, further improving its accuracy one image at a time.

Smart Data Mining and Data Historization for an Intelligent Control Center

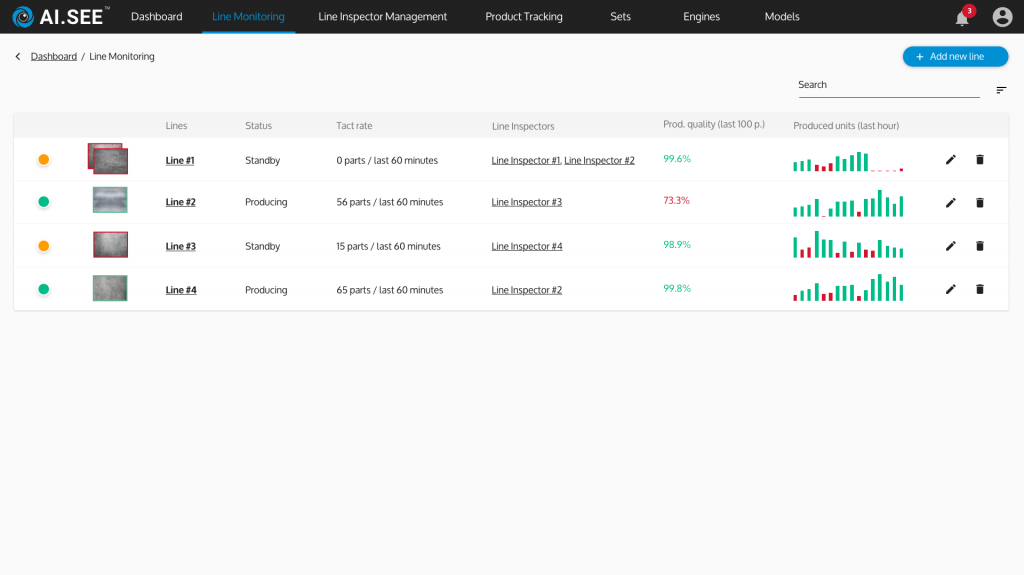

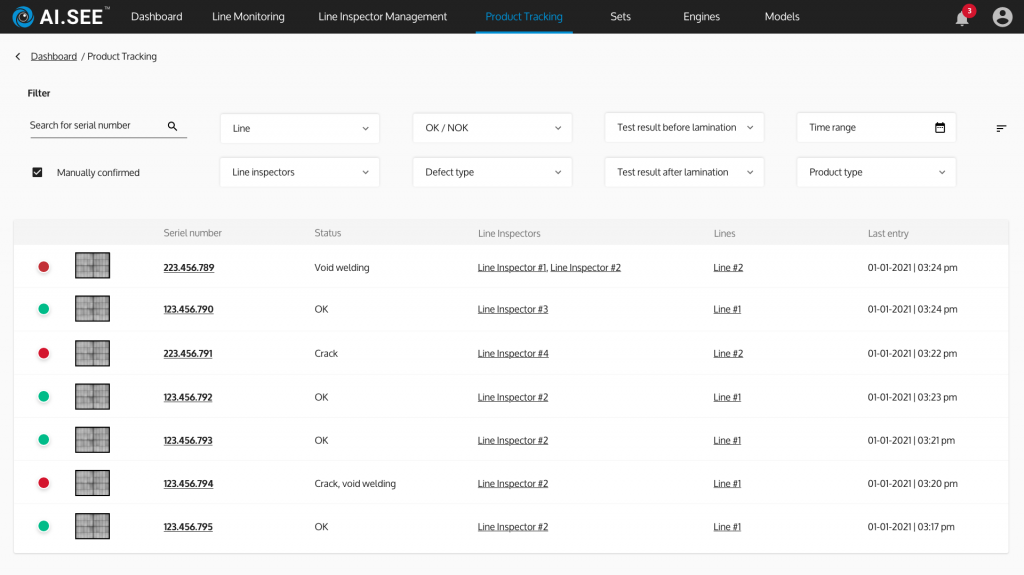

With AI.SEE™, you gain full visibility into where exactly your entire production stands. Thanks to smart data mining, you can thus collect unlimited amounts of historical image data, annotations, and evaluations for future use in other AI-based systems. Within seconds, vast amounts of data can be accessed either through comprehensive filtering options in AI.SEE™’s GUI or via software access using HTTP interfaces. If required, the AI.SEE™ Core harnesses image and defect data to visualize the production quantity and quality rate in an OEE cockpit – be it cross-production or for every single production line. It also enables product tracking across multiple process steps, either through the connection of standardized interfaces or, if required, integrated into your customized web interface.

Features

Can Artificial Intelligence Automate Your Optical Inspection?

When it comes to supporting companies in manufacturing, similar challenges and concerns frequently arise. To provide you with a proper evaluation of the feasibility and price, please fill out the questionnaire below.

Find out whether AI can solve your problem by answering just a few questions:

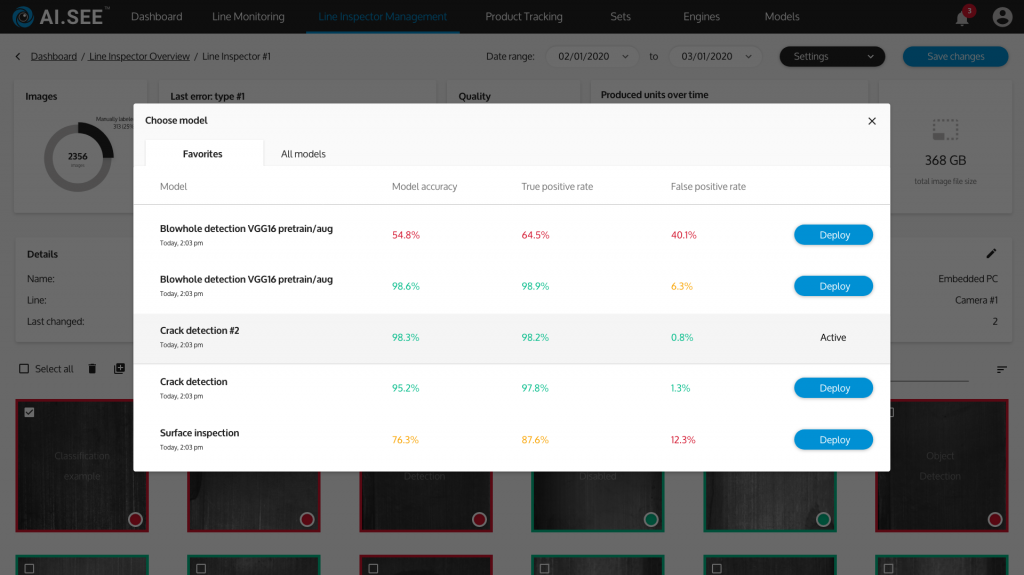

Continuous Automated Enhancements of AI

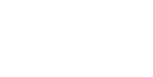

You can annotate the collected image data in AI.SEE™ Core enhancing the self-learning backend-AI to keep perfecting its training. AI.SEE™ Core also eases data understanding by providing insights into image analysis and recognition rates, visualized with descriptive metrics.

Smart annotation sorting supports prioritized annotation of relevant data to avoid annotating every single image while still maximizing the training effect for the models.

Integration Into Existing Systems

To integrate AI.SEE™ into existing IT architectures, elunic offers APIs providing functions such as image upload, download, analysis, reports, ERP connection, and much more.

Classification Options

Operating AI.SEE™ Core — Online or Offline As Desired

AI.SEE™ Core – Online

AI.SEE™ Core Online is a cloud-based portal with frontend and backend. This allows the collected image data to be annotated to enhance the self-learning backend-AI over the cloud continuously.

AI.SEE™ Core – Offline

As an alternative to the online solution, AI.SEE™ can operate on-premise right on the shop floor running on dedicated hardware, consisting of an industrial computer with a high-performance GPU.

System Expansion With AI.SEE™ Line Inspectors

The AI.SEE™ Core is complemented and extended by AI.SEE™ Line Inspectors, smart cameras, and AI evaluation tools installed on each production line and managed via the AI.SEE™ Core. Each Line Inspector evaluates all incoming images received from its line and uses the analysis results to control the downstream processes.

References

Contact.

Do you have a project inquiry or just want to say hello? Please do not hesitate to contact us – we will be happy to answer you immediately.