Reliable Error Detection and Prevention Through Artificial Intelligence

Due to ever-increasing quality expectations of both the processing industry and consumers, efficient quality control has become indispensable. Particularly in the processing of metals and plastics, many production defects can occur that conflict with this quality requirement. Reliable, flawless defect detection, such as cracks in stamping parts, is therefore essential. Detecting these defects can significantly reduce additional rework costs and reduce or even prevent the financial loss associated with rejects. Furthermore, adequately implemented crack detection or other production defects substantially increases quality and efficiency.

Cracks – A Common Production Defect

In general, a crack represents a discontinuity in material or the finished product due to manufacturing or operational causes. If the crack length exceeds a critical threshold, the required stability is no longer given, and the material breaks along the crack. By far, the worst consequence of a crack is the complete breakage of the material, which is why they are frequently referred to as one of the most dangerous material defects in production.

In particular, a resulting inhomogeneous stress ratio around the crack often leads to noticeable flaws or deterioration of quality due to loss of structural strength and, for example, in the automotive industry, can result in considerable rework costs or even worse consequences.

Cracks differ in size and shape in endless ways. Regardless of the influencing factors involved or the actual appearance of a crack, it usually proves to be a critical production defect. Even minor cracks can increase in size over time or during further processing.

However, avoiding cracks is not possible , which is why ways must be found to integrate reliable crack detection into the production flow. Thereby, the aim should be to detect cracks at an early stage to counteract their causes in production immediately.

With just a few questions,

find out now whether AI.SEE™ can solve your problem:

Increase Quality in Production Through Automatic Detection of Cracks

While some industries continue to rely on traditional quality inspection methods such as manual visual inspection, other industries have already recognized the benefits of automated quality inspection. In the automotive industry, for example, automatic crack detection in production leads to significant efficiency gains and quality improvements and has a cost-cutting effect.

When the optical inspection is carried out by trained staff, numerous aspects need to be optimized. Visual inspection carried out by humans is error-prone, expensive, and often too slow to ensure an efficient process flow, even though employees are extensively trained and highly skilled. Besides, fluctuation in concentration levels along with a person’s physical and mental condition make it very difficult to ensure reliable, consistent, and objective results.

To avoid these fluctuations in the inspection results, every part produced in production must be analyzed according to the same standards, and critical cracks must be detected quickly and reliably. Furthermore, proper classification and extensive documentation of production defects are of great importance. Automated crack detection can satisfy these quality control requirements. In order to achieve a measurable improvement in the existing production process, it should also be possible to implement a fully automated, software-based solution in the current system. For this reason, elunic has been developing advanced Industry 4.0 solutions that utilize AI to automatically detect cracks during production in a cost-efficient and stable manner. This can save big investments in staff training and avoid errors due to fluctuations in individual human fitness. As a result, efficient quality assurance processes lead to a significant increase in the overall quality of the end products.

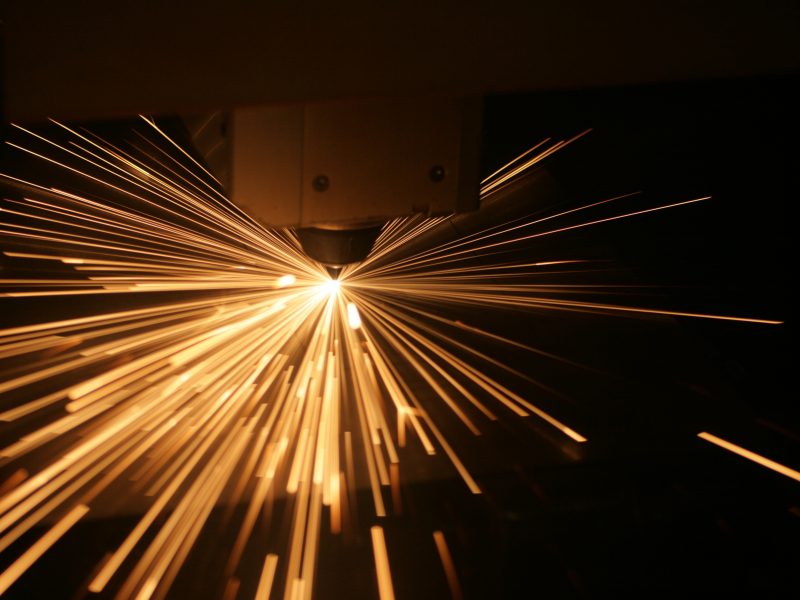

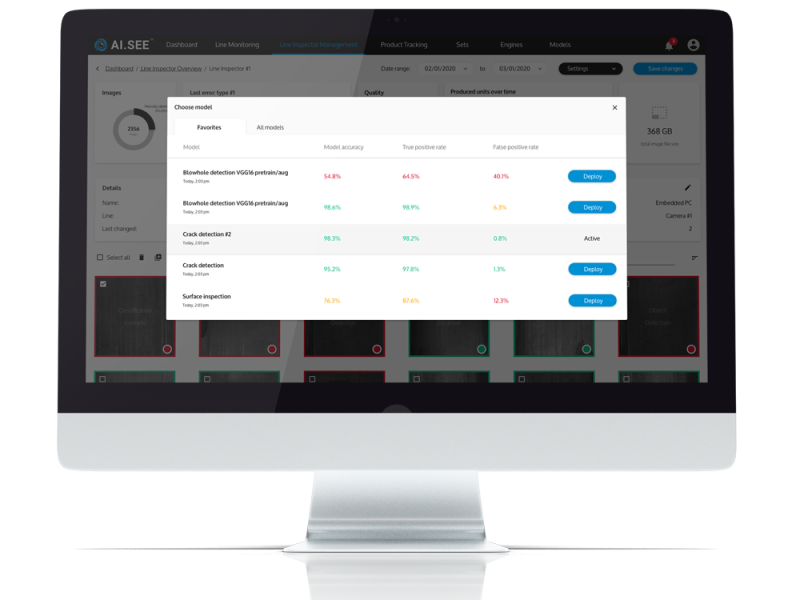

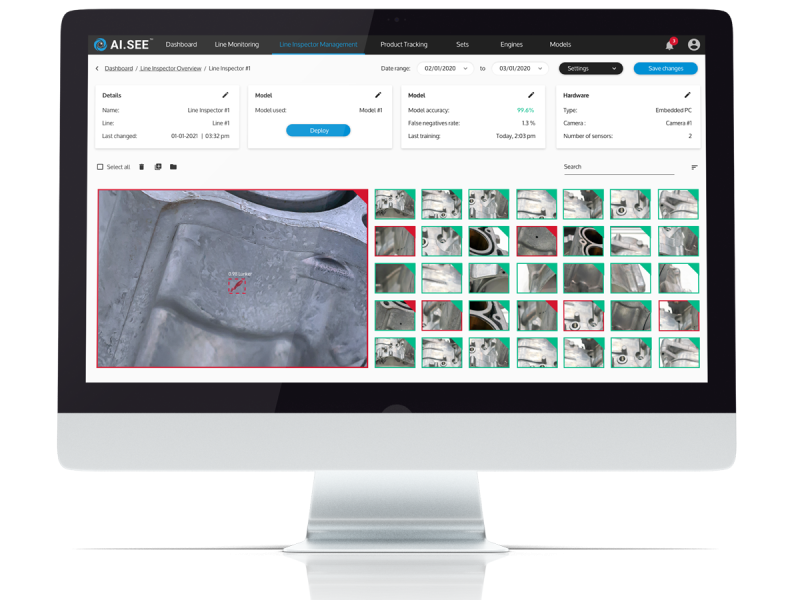

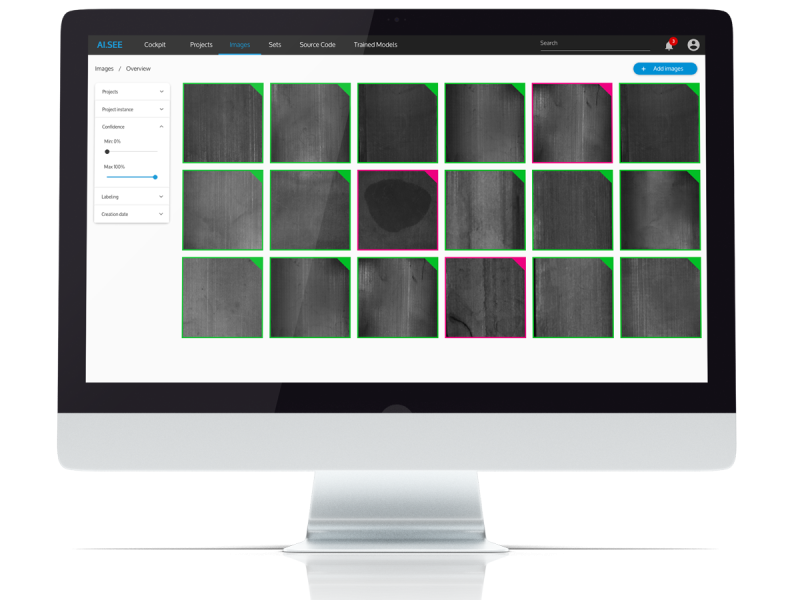

AI.SEE™ – The Efficient Solution for Automatic Crack Detection

elunic’s automated quality control AI.SEE™ is a production-specific programmed application that can analyze and inspect each part autonomously for any kind and size of cracks along with other production defects. With its simple and intuitive handling, AI.SEE™ is the perfect solution for optical inspection of all crack-prone materials, reliably detecting and documenting cracks powered by artificial intelligence. Extensive feeding with unique training data permits the creation of an adaptive learning model based on different error patterns and rejection criteria. This model is constantly evolving and is thus capable of reliably detecting even the smallest material cracks. Additional defect patterns in ongoing production or new product series can be integrated into the system in just a few steps. Its simple and intuitive operation ensures that every QA employee can feed the tool with training data. The open system architecture also provides opportunities for other business units and external service providers to develop models or pipelines and integrate them into the system.

The extensive collection and analysis of data by the Cloud-based software enable comprehensive backtracking of defect-prone components and their reworking in the respective production step. Apart from measures to optimize future production batches, the implementation of real-time monitoring offers numerous other opportunities to reduce waste.

Are you interested? Learn more about the numerous possibilities for optimal detection of cracks with AI.SEE™!

Further Reference Projects

References

Learn more about the project.