AI.SEE™ – Automated Visual Inspection of Production Quality using Artificial Intelligence (AI)

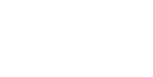

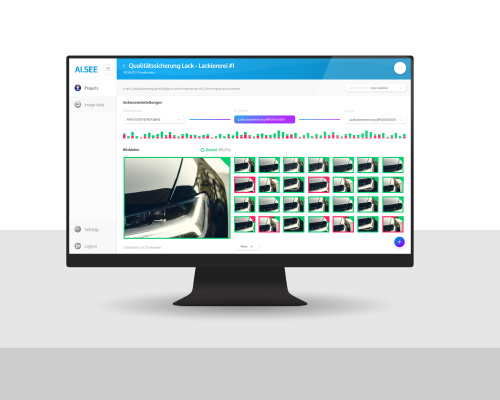

AI.SEE™ is an artificial intelligence-based visual quality control and defect detection system for manufacturers, consisting of the self-learning AI.SEE™ Core and the AI.SEE™ Line Inspector modules – smart cameras and AI evaluation tools installed directly on the assembly line and managed via the Core. Incoming images are evaluated at the assembly line and further processes are controlled.

Challenges in Quality Assurance

The demands put on modern manufacturing facilities are tremendous: They are expected to be highly productive, flexible at maximum quality, cost-efficient, and trouble-free.

The process of manual visual inspection and other conventional quality inspections are usually unreliable, expensive, have a low detection rate and are difficult to scale.

Reliable Solutions for Quality Assurance with Automated Optical Inspection (AOI)

New technology brings new solutions for quality assurance. Automated optical inspection (AOI) is an automated visual inspection method that scans for product deficits and failures along the assembly line. The commonly used visual inspection by the eye of an employee is replaced or supported by automated optical inspection (AOI) through camera systems. These automated visual inspection solutions inspect components precise, fast and without gaps along the assembly line, which makes the technology more reliable and more efficient than the human eye.

By taking advantage of the possibilities offered by artificial intelligence, the AI.SEE™️ equipment enables producers to perform a non-destructive, reliable, and automated visual inspection of their products.

With deep-learning algorithms, AOI can find even the smallest defects on heterogeneous or reflective surfaces that an visual inspection by humans often misses and deliver potent insights while maintaining and improving reliable quality and operational efficiency.

So by using automated visual inspection systems manufacturers can inspect products with high accuracy and increase production quality. Automation of visual inspection reduces manual inspection time and increases producing speed, leading to increased efficiency. By increasing efficiency and reducing defects, an automated visual inspection can lead to lower production costs and improved profitability. In addition to that an automated optical inspection system can provide valuable data on product quality and production processes that can be used for continuous improvement.

AI.SEE™ Product components

AI.SEE™ Line Inspector

The AI.SEE™ Line Inspector is part of the AI.SEE™ suite. The equipment is installed on the assembly line providing its own cameras or interfacing with existing cameras. It analyzes the camera images locally and controls the downstream process.

AI.SEE™ Core

With the AI.SEE™ Core, you collect and manage large volumes of quality assurance data and images. AI.SEE™ automatically trains the AI-assisted, self-learning, neural-network-based error-detection algorithm, further improving its accuracy with every new image.

Features

- Annotation of Images

- Projects and User Rights

- Neural Networks

- Dashboard and Analyses

- Interfaces for Imaging Systems

- Interface for Deployment

- System Integration Interfaces

Annotation and Management of Image Data

With AI.SEE™️ Control, individual images can be inspected in detail, annotated, and assigned to defect classes. Furthermore, images can be managed in sets and assigned to projects to use them for training and retraining of different deep learning models.

Management of Projects and User Rights

Individual projects can be managed and analyzed within the AI.SEE™️ project database.

Moreover, personalized access to functions, projects, and elements within AI.SEE™️ can be defined for individual users.

Training, Deployment, and Evaluation of Neural Networks

AI.SEE™️ trains neural networks for error detection in the background. Should defects or components change, AI.SEE™️ Control can adapt to those changes and enable a seamless transition between different product groups. Neural networks are trained, deployed, and evaluated within the system.

Dashboard and Data Analysis

The AI.SEE™️ technology allows you to manage images, failure classes, training data and results in well-structured dashboards. For example, statistics and trends can indicate the wear and tear of production machines at an early stage.

Interfaces for Different Imaging Systems

With AI.SEE™️ Lens, elunic provides its own camera and lighting system, while also enabling a seamless integration to existing systems.

Interface for Deployment of Own Architectures and Models

Due to the rapid progress of machine learning technology, any neural network architecture can be used. Their deployment can be achieved by the simple implementation of the AI.SEE™️ Engine interface.

Interfaces for System Integration in MES/QMS/…

To enable continuous production in a large factory, a precise allocation to each production piece is essential. This also includes marking if such production items do not meet the quality requirements.

AI.SEE™️ Benefits

Can Artificial Intelligence automate your Visual Inspection?

When it comes to supporting companies in manufacturing, similar challenges and concerns frequently arise. To provide you with a proper evaluation of the feasibility and price, please fill out the questionnaire below.

AI.SEE™️ Presentation at the IAS in Shanghai

``Data is the new gold. Image data can be managed and annotated in the central data hub. The setup takes less than 30 minutes on average!``

Rule-Based Computer Vision vs. Deep Learning

Rule-based computer vision used in conventional AOI test systems only deals with identifying images based on fixed rules for the recognition of lines and shapes.

In contrast, AI.SEE™️ uses machine learning models that learn the interrelations between diverse and most complex data sets in real-time using state-of-the-art artificial neural networks through deep learning. These enhanced adaptabilities not only provide superior quality but also improve the performance of production equipment.

AOI (automatic optical inspection) enables fast and accurate automated inspection of electronic assemblies, e.g., to ensure high product quality in PCB manufacturing. Surface inspection, position, orientation sensors of electrical components, and classifications are only a few examples of the system’s application possibilities. Unlike conventional image processing systems, AI.SEE™️ uses state-of-the-art technology to detect and locate objects and defects more efficiently and improves the throughput and ease of use.

``For producers and machine manufacturers, AI.SEE™️ provides ideal solutions on your way to connected factory and Industry 4.0.``

4 Steps towards AI-supported Quality Assurance

Step 1:

Proof of Concept

1 defect class on 1 material/product

Start straight away and validate your AI-based quality assurance project fast, cost-efficient, and convenient with an online showcase to detect a defect class on a material or product. Our experts are ready to support you and help you find the right camera system for your solution or to install our own camera and lighting equipment—AI.SEE™️ Lens.

Camera system: If you already have an existing camera system installed, we can dock onto the system used without any problems.

Step 2:

Comprehensive Online Use Case

All defect classes on all materials/products

In the second step, the project will be extended by training the deep learning models with the help of automated optical inspection systems. The deep learning model will be further trained to detect all defect classes on all materials and products in your production and to directly display and analyze the different defect classes on newly uploaded images.

Step 3:

Autonomous Installation in Production

All defect classes on all materials/products

After training your AI.SEE™️ project for all defect classes across all materials or products, you will receive your ready-for-use detection solution on AI.SEE™️ Edge, our performance computing system optimized for artificial intelligence, to integrate image analysis into your manufacturing process.

Step 4:

Retraining and Remote Quality Assurance

All defect classes on all materials/products

To ensure a high detection rate, AI.SEE™️ launches into production with high error sensitivity. False positives are marked as such during operation to reduce the number of error messages on error-free images (false positives). With this data, AI.SEE™️ continues to learn automatically, reducing the number of false positives daily.

Remote Quality Assurance: Enable your staff to access quality control results and make annotations regardless of where they are located.

AI.SEE™️ Products

AI.SEE™ Lens

AI.SEE™️ Lens is a versatile camera and illumination system that contains an optical lens and integrated lighting, specially optimized for surface inspections within industrial production processes.

AI.SEE™ Edge

AI.SEE™️ Edge analyzes captured images locally and controls further processing depending on the result, e.g., automatic separation of defective products or displaying warning messages.

AI.SEE™ Control

AI.SEE™️ Control is a cloud-based portal on which the gathered image data can be annotated to develop the self-learning A.I. behind it continuously.

``AI.SEE™️ runs in the cloud or on your shop floor. And you can test the software for one month for free.``

References

Contact.

Do you have a project inquiry or just want to say hello? Please do not hesitate to contact us – we will be happy to answer you immediately.