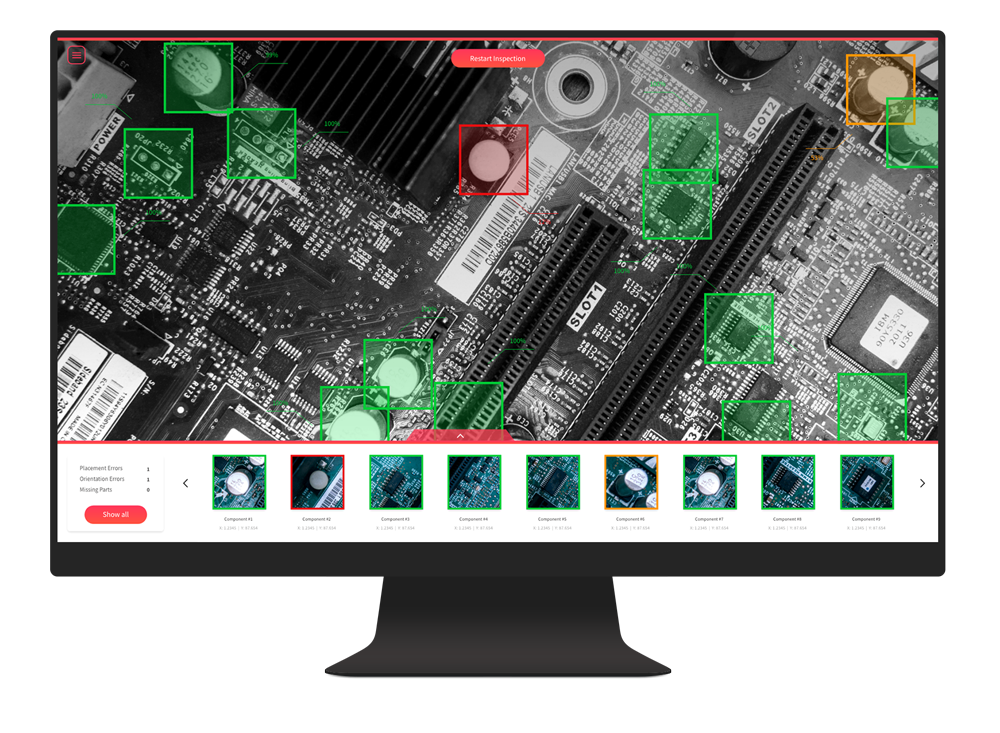

Automatic SMT (surface-mounted device) inspection

Challenges

Inspections to find faults in the PCB mounting process are still carried out manually by a worker on site.

In order to simplify this process and to reduce the amount of errors, elunic was commissioned to develop a system based on artificial intelligence that automatically detects errors.

Key Features

- Anomaly detection and classification during circuit mounting.

- Dashboard with a circuit board inspector and evaluation of results.

Solutions & Services

- Implementation and roll-out of an A.I.-based Circuit Board Inspector.

- Generation of image data to train machine learning algorithm.

- Use of Automated Optical Inspection (AOI).