Quality Assurance in the Press Shop and Metal Stamping —

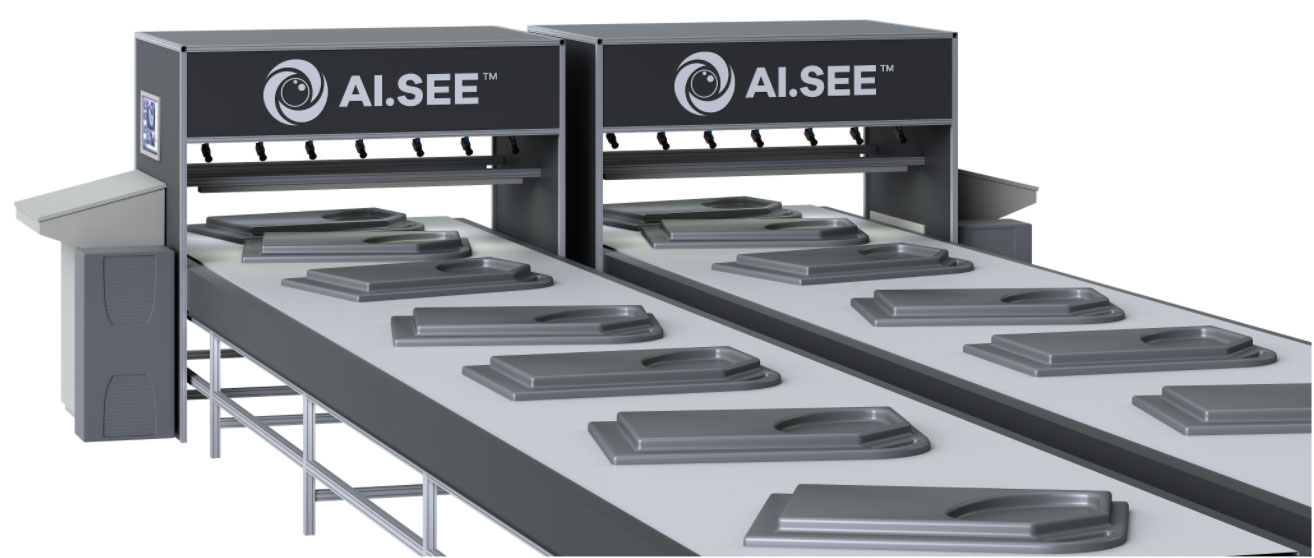

Sheet metal parts are among the most important semi-finished products, especially in the automotive industry, and are processed by forming in the press shop of a production line. Implementing a full-scale visual quality assurance process—powered by artificial intelligence—can increase efficiency and thus reduce costs. By retrofitting your press shop with elunic’s AI.SEE™, you will make your press plant competitive again.

Conventional optical Industry Quality Inspection

Even today, quality inspectors are still widespread in the industry when it comes to quality assurance. They visually inspect the production parts on the outfeed conveyor to ensure that they are defect-free. However, this QC inspection method cannot guarantee 100 % coverage without digitization because it is hampered by human errors and time constraints.

Manufacturing Processes at Press Plants

Knowing the production process is paramount in order to optimize the quality control of sheet metal parts. Their production is dominated by a metal-forming process, consisting of rolling, open-die forging, swaging, extrusion, deep drawing, stamping and bending that neither adds nor removes material, as it keeps its mass and cohesion.

But before machine forming can take place in the press shop, the malleable material has to be brought to the correct size. Therefore, the raw materials are meticulously pre-processed in the press shop’s cutting department using cutting machines, slitting machines, or lasers.

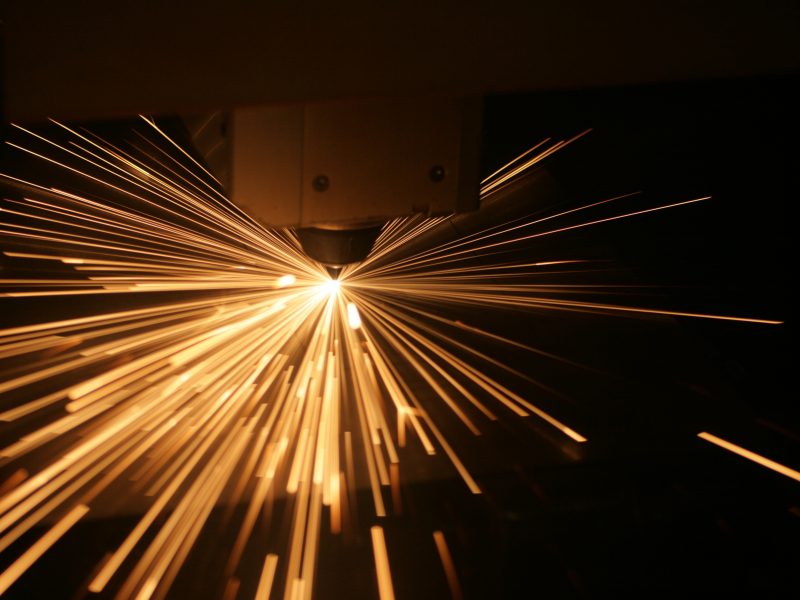

Typical Defect Patterns of a Pressing Plant: Neckdowns, Cracks & More.

Frequent error patterns found in formed components are cracks, wrinkles, necking, breaks, and scratches. If the supplied raw material quality is already substandard, this can quickly degrade the quality of workpieces produced by the press shop. Yet, other factors, such as run-up effects or tool tolerances, also play a part in the manufacturing process and can prevent quality requirements from being met during production.

The Press Shop and Metal Stamping in Industry 4.0

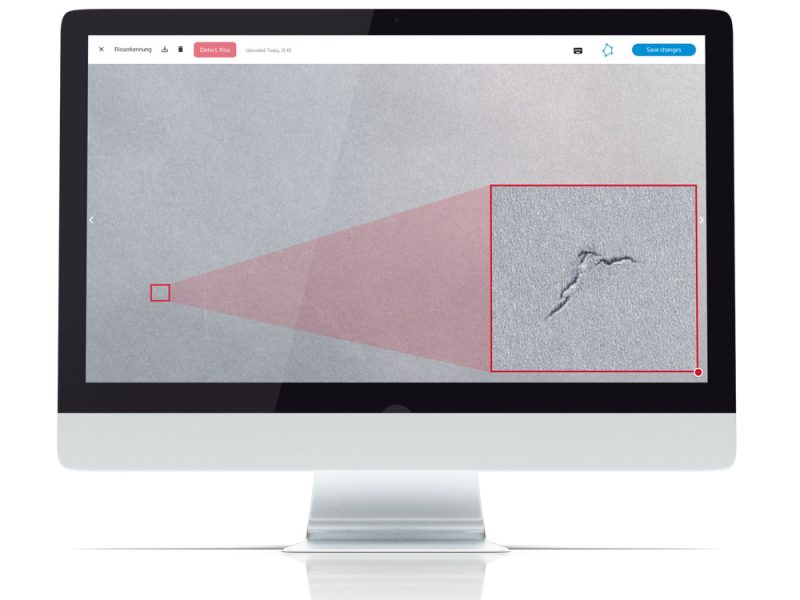

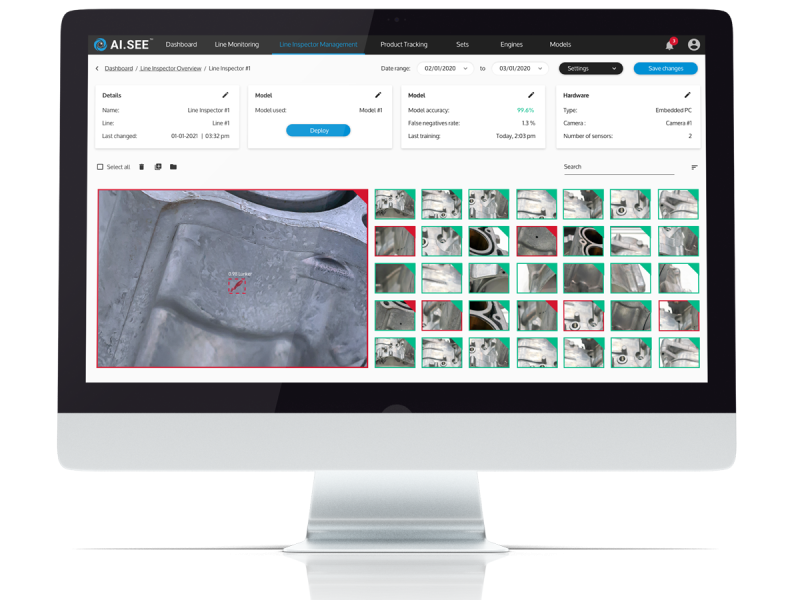

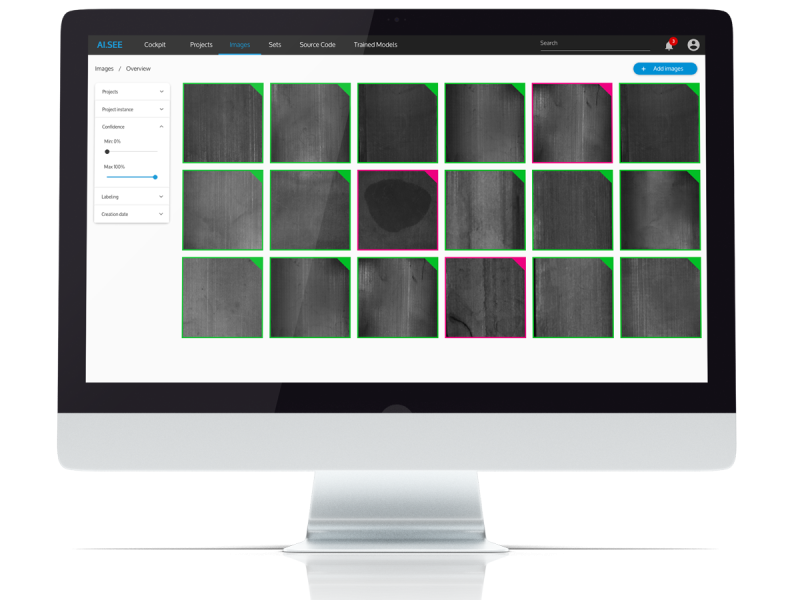

The advent of advanced artificial intelligence in all corners of the shop floor opens up new applications for modernizing quality assurance in the press shop. Conventional optical quality control methods have reached their limits, mainly due to the time required for visual inspection. To guarantee efficient and zero-defect inspections of every part produced, technical means are indispensable, and even they quickly reach their limits without artificial intelligence. Codified algorithms used to analyze sensor data of quality-relevant characteristics are highly complex and costly to develop. Even worse, they lack flexibility since their procedure must be precisely defined beforehand, and the manufacturer must carefully control the operational environment.

In contrast, an optical quality inspection can boost efficiency and guarantee total in-line quality control thanks to smart inspection methods. For a press shop, this means that every production part can be inspected for quality defects right at the press exit and that defects can be corrected on the spot.

With Just a Few Questions, Find Out Now Whether AI.SEE™ Can Solve Your Problem:

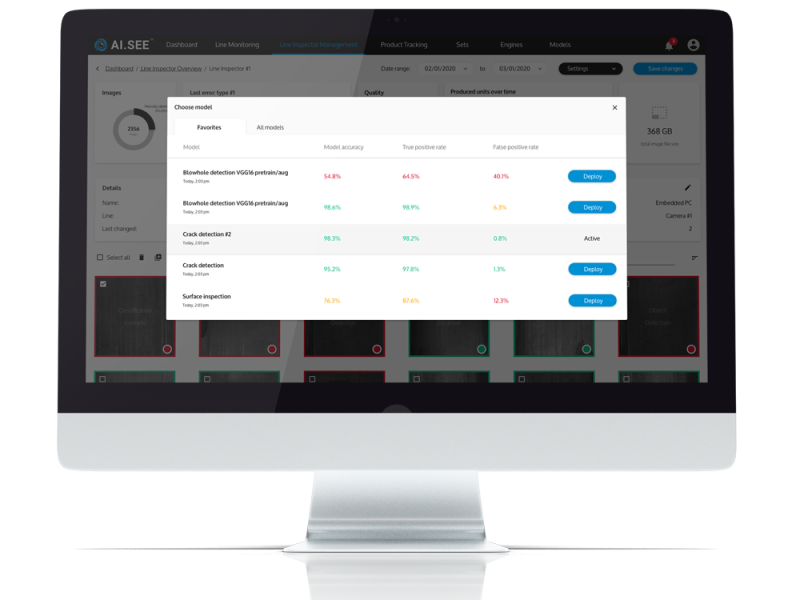

Retrofitting: Digitizing a Press Shop with AI.SEE™

Modernizing your presses or even entire press lines to remain competitive sounds like a costly undertaking at first. Yet, the latest digitalization technology in Industry 4.0 promises significant productivity gains at lower production costs by retrofitting your press shop without replacing the entire hardware.

By using AI.SEE™, the quality assurance of your press shop can be fully modernized without replacing the whole press line. Once our automation experts have thoroughly analyzed your press shop, they will provide you with the best solution for optimizing your quality control. Thanks to artificial intelligence, you can now use elunic’s AI.SEE™ to solely check your parts with optical quality inspection. This means that the press shop does not have to undergo costly modifications. Fitting standardized cameras is sufficient to implement quality assurance on par with a trained QA operator. With Retrofitting, your press shop will also enjoy longer maintenance intervals. Maintenance often becomes a costly factor for assets that have been in service for quite a long time. Modernization thus leads to efficiency and productivity gains, as well as lower maintenance and servicing costs.

Further Reference Projects

References

Learn more about the project.