Optical inspection (or visual inspection) describes the optical examination of a product or part for flaws or production defects. Thanks to digitization, people are turning to applications based on AI (artificial intelligence) to efficiently and accurately inspect products. As a non-destructive quality assurance method, optical inspection is ideal for detecting scratches or cracks, blowholes, casting defects, or other external nonconformities.

Optical inspection in quality assurance

When it comes to visual quality assurance, companies frequently rely on trained employees instead of an automated visual inspection system. However, manual visual inspection regularly proves not to be the best method for quality assurance. Steadily increasing quality demands by customers and the manufacturing industry have pushed manual optical inspection to its limits. Although a non-destructive optical inspection can often be seamlessly integrated into the production process without causing significant disruptions, problems with efficiency and consistency frequently occur with a manual inspection. If quality requirements demand a visual inspection of every single production unit, an optical inspection by operators no longer meets the required takt times under most circumstances.

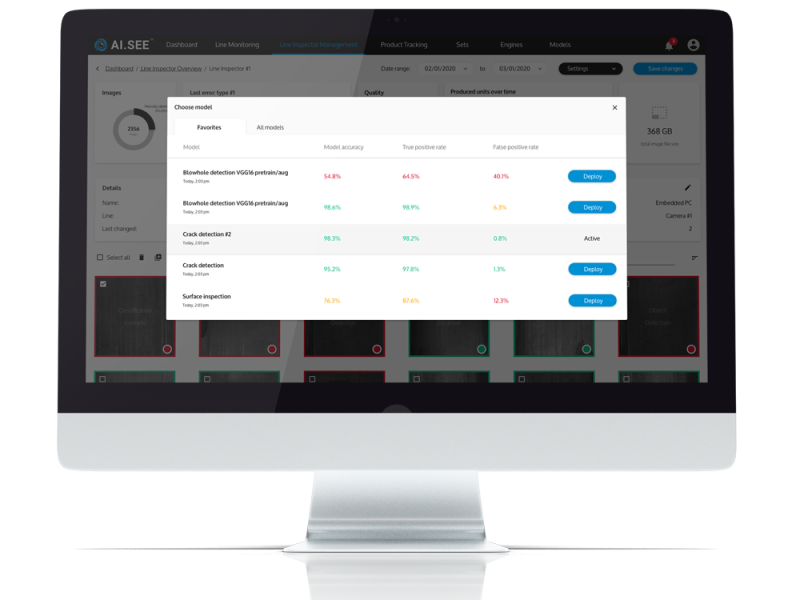

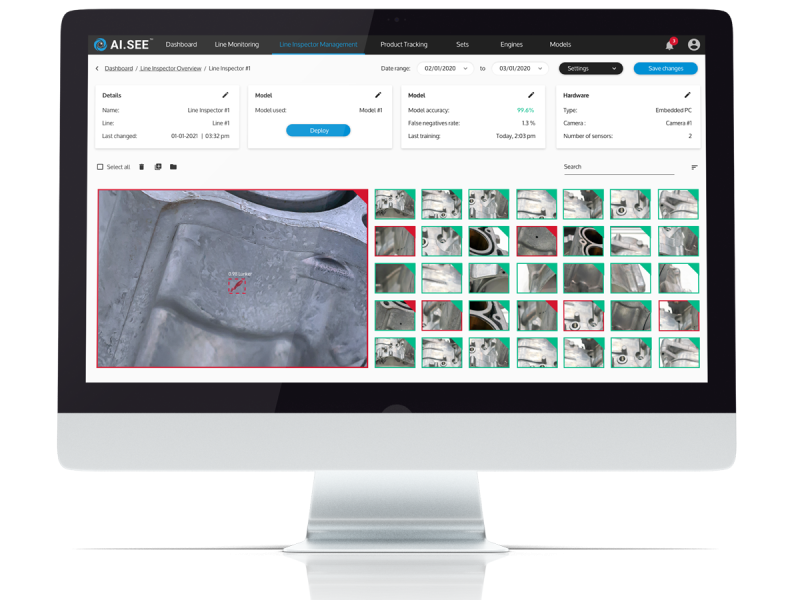

Automated optical inspection with AI.SEE™

An automated, AI-based optical inspection solution using inspection software will bring significant efficiency gains. In addition, AI-based autonomous optical inspection leads to a substantial increase in quality by avoiding fluctuations in the quality of the finished product.

By using AI.SEE™, every produced item can be efficiently and reliably inspected against predefined criteria. It also allows the defects to be marked and documented to prevent their reoccurrence in the future.

With just a few questions, find out now whether AI. SEE™ can solve your problem:

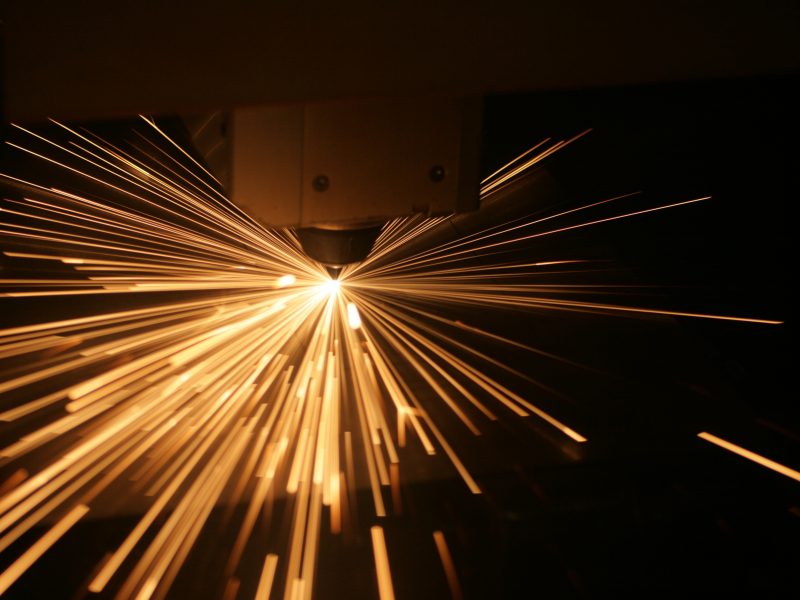

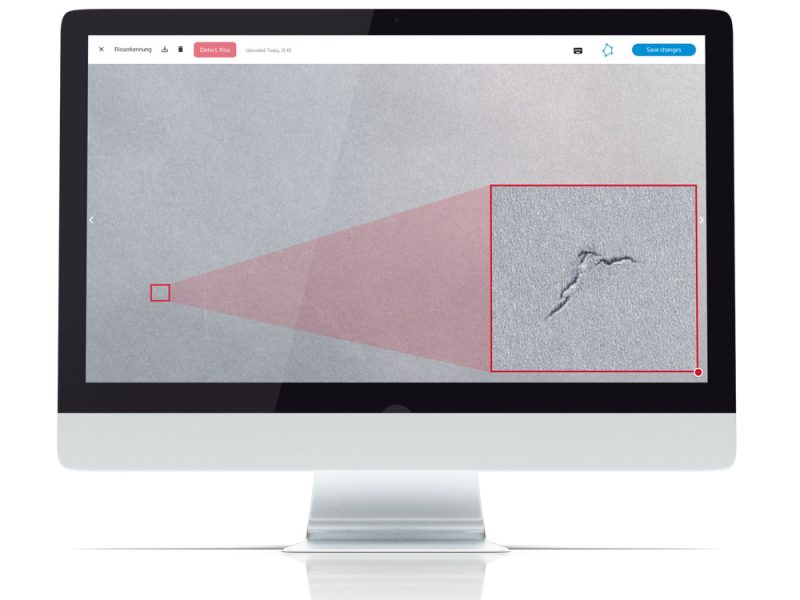

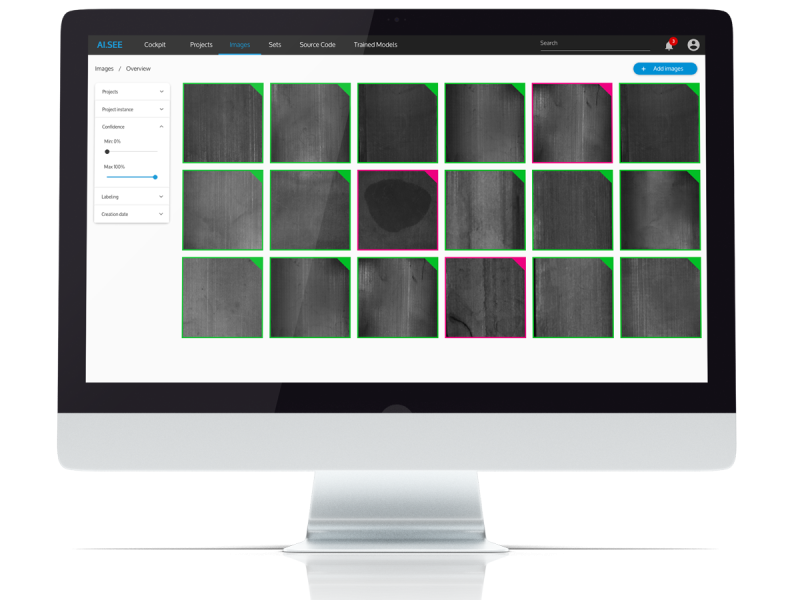

A real-world example of optical inspection—defect detection in solar cell production

Conventional vision-based defect detection systems use hard-coded rules to detect specific shapes or lines. In contrast, AI-based optical inspection with AI.SEE™ from elunic relies on neural networks trained with extensive data sets and AI.

It takes a skilled operator about 60 seconds to visually inspect one solar panel, checking for four main types of defects. The AI-based inspection system from elunic checks the same component in less than 5 seconds and afterward presents its results to the operator for confirmation. Hence, the inspectors only check the critical areas of the solar panels with their trained eyes, which takes them just 10 seconds.

Besides saving a great deal of time, the reduced optical inspection efforts offer yet another advantage: the AI-based inspection system remains consistently reliable and unaffected by physical and mental fatigue to which a human is exposed—even after long working hours. This way, the inspector’s limited attention span can be efficiently spent precisely on those areas that need visual inspection. And thanks to the AI.SEE™ inspection system, an even better detection rate of production defects can be achieved.

A real-world example of optical inspection—defect detection in solar cell production

Consultancy

Consultancy on business areas, procedures, and technical challenges.

Development

Architecture, programming, and maintenance of tailor-made software solutions.

Integration

Integration of the most essential platforms and on-premises solutions.

Further Reference Projects

References

Learn more about the project.